Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Applicazione: TUBO

Elaborazione Del Tipo Di Plastica: PE, PP, PPR, HDPE / PP, PE / PP

Stato: Nuovo

Design A Vite: Vite singola

Materiale Della Vite: 38CrMoALA

Diametro Vite (mm): 65

Rapporto Tra Lunghezza Della Vite E Diametro: 33: 1

Posizione Dello Showroom (in Cui I Paesi Ci Sono Sale Campioni All'estero): nessuna

Luogo D'origine: Cina

Periodo Di Garanzia: 1 anno

Punto Di Forza Core: Risparmio energetico

Servizio Fuori Da Guerra: Supporto tecnico video, Supporto online, Servizio di manutenzione e riparazione del campo

Dove Fornire Servizi Locali (in Cui I Paesi Ci Sono Punti Vendita All'estero): Nessuno

Industria Applicabile: Negozi di abbigliamento, Negozi di riparazione di macchinari, Fabbrica di alimenti e bevande, Tipografie, Negozi di alimentari e bevande, Compagnia pubblicitaria

Tipo Di Marketing: Nuovo prodotto 2020

Ispezione Di Fabbrica Video: Fornito

Rapporto Di Test Meccanici: Fornito

Periodo Di Garanzia Dei Componenti Core: 1 anno

Componenti Principali: Il motore, Pompa, Riduttore, Vite

Pacchetto: Un bancale di legno

Trasporti: Ocean

Porta: Shanghai Port

Tipo di pagamento: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

PLASTIC PPR PE MULTI LAYER PIPE PRODUCTION LINE

PLASTIC PPR PE MULTI LAYER PIPE PRODUCTION LINE:

PLASTIC PPR PE MULTI LAYER PIPE PRODUCTION LINE is a new product developed by our company by introducing and absorbing foreign advanced technology. Its screw, die and other key components are specially designed according to the characteristics of ppr. Through the three-layer coextrusion technology, the spiral three-layer co extrusion die with special design is adopted to ensure the uniform thickness of three layers and the thickness of each layer can be adjusted arbitrarily. Spiral split die can be equipped with static mixing system. The material layers are fully overlapped with each other. Compared with the traditional support die head, the internal pressure is more uniform. In the form of ABA, the glass fiber in the middle reinforcement layer is arranged regularly, and organically melts with the inner and outer PPR layers to form a whole, which significantly overcomes the overhanging phenomenon of the pure PPR pipe in surface installation, and reduces the linear expansion coefficient of the pipe. Compared with pure PPR pipe of the same specification and pressure grade, it can save material, reduce cost and be more competitive. The production line is equipped with automatic vacuum feeding machine and automatic constant temperature dryer; the designed vacuum sizing and cooling system is made of stainless steel water tank and cooled by multi-stage water mold to ensure the requirements of high-speed production of thick wall pipe and large-diameter pipe. High torque reducer, frequency converter, PLC, touch screen, electric control system, inkjet printer and so on are imported products. New chip free automatic cutting saw, smooth cutting section, high precision, low noise and so on. It can produce HDPE silicon core pipe, ordinary PPR, PE, PEX pipe. Provide process formula and turnkey project.

Characteristics of PLASTIC PPR PE MULTI LAYER PIPE PRODUCTION LINE :

1. This machine is mainly used for pipe production with PPR resin as raw material. 2. The design of slotted feeder barrel and barrier screw can improve the plasticizing effect. 3. High extrusion rate, low melt temperature and uniform temperature. 4. Barrier type two pole mixing, ie special screw for day, slotting barrel. 5. Equipped with a new type of secondary split die, with the characteristics of low temperature and low pressure extrusion: water film sizing sleeve, to ensure the high-speed production of pipes. 6. The production line is controlled by PLC, and PPR cold and hot water pipe production line manufacturer has good man-machine interface. 7. The marking line can be selected to extrude to produce the pipe with color mark. The production line can produce PE pipe by changing mould. 8. Random polypropylene production line is mainly used to produce pipe production line with PP-R resin as raw material, and also suitable for pipe production with PP, Pb and PE resin as raw materials. SJ-65 / 33 is used as extruder, equipped with corresponding mould, cooling device and traction device, which is used for continuous and efficient extrusion of pipes. It has the characteristics of stable quality and convenient operation.

PLASTIC PPR PE MULTI LAYER PIPE PRODUCTION LINE PROCESS

Drying of raw materials→ Extrusion molding → Vacuum sizing → Spray cooling → Haul-off → Fixed length cutting → Pipe filling and unloading

PLASTIC PPR PE MULTI LAYER PIPE PRODUCTION LINE PHOTOS

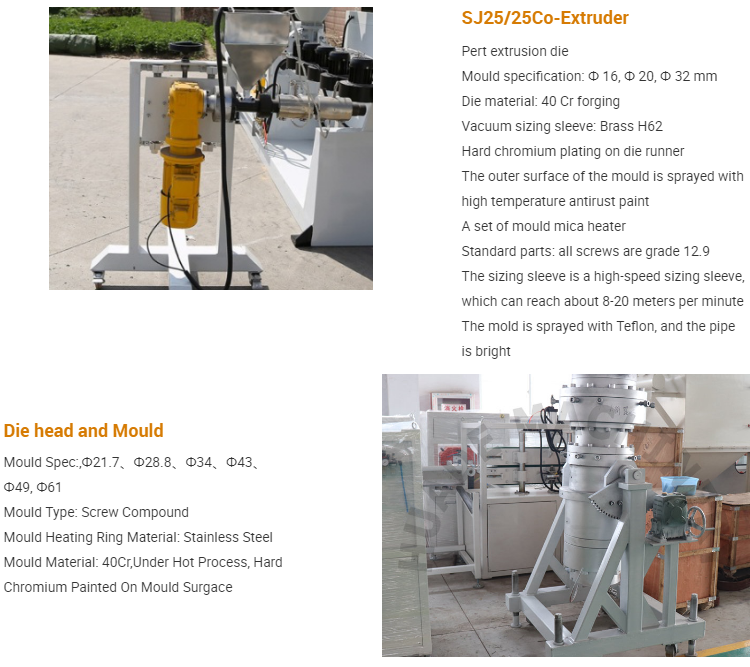

SJ65/33 extruder of PLASTIC PPR PE MULTI LAYER PIPE PRODUCTION LINE

1. Single screw extruder: model SJ65 / 33

2. Cylinder and screw material: 38CrMoAlA,

3. Cylinder and screw structure: barrier screw, asymmetric slotted barrel design.

4. The gearbox is equipped with strong thrust bearing and high torque output; the gear is made of special alloy, with hard tooth surface and gear grinding process;

5. Temperature control table of OMRON

6. ABB or Siemens brand inverter

7. Schneider or Siemens AC contactor

8. Siemens Bede motor

9. Diameter of screw: Φ 65mm

10. Length diameter ratio of screw: 33:1

11. Driving motor power: 55kW high speed screw

12. Gearbox : high torque, low noise, hard tooth surface grinding reducer is equipped with external cooling circulation system

![%X7]3_3)P1F`Z8)H{P$IZ46 %X7]3_3)P1F`Z8)H{P$IZ46](http://bsg-i.nbxc.com/product/57/e5/10/3661ccf114bb06b4874e588f2c.png)

![26}0CO[_{GNS}`PP]SIBIIY 26}0CO[_{GNS}`PP]SIBIIY](http://bsg-i.nbxc.com/product/22/8d/4d/e5a4b9ed2d7fee3d7f08c337fb.png)

![{]LTKZG95X7S6RQ%DXL%WK2 {]LTKZG95X7S6RQ%DXL%WK2](http://bsg-i.nbxc.com/product/cb/b5/15/da52f89af72edfdc4caceac211.png)

![3W]E40_WY3WCSFWB%U0%~]L 3W]E40_WY3WCSFWB%U0%~]L](http://bsg-i.nbxc.com/product/03/44/5d/d88d430f785326d5d986008ea0.png)

Packaging of PPR glass fiber pipe co-extrusion plastic machine

Exhibition of PPR glass fiber pipe co-extrusion plastic machine

Elenco prodotti : Linea di estrusione di tubi PPR PPRC

mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.